OEM Air Ride Springs 260130H-1 One Covolution Rubber Air Actuator

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | 260130H-1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Material: | Rubber And Steel | Certifications: | ISO/TS16949:2009 |

|---|---|---|---|

| Warranty Period: | 1 Year | Number Of Convolutions: | Single |

| Packing: | Neutral Box Or As Customers' Request | Type: | Air Springs |

| Cross Reference: | 260130H-1 | OEM: | Welcome |

| Quality: | 100% Tested | Applications: | Industrial Or Others |

| High Light: | OEM Air Ride Springs,Air Ride Springs 260130H-1 |

||

Product Description

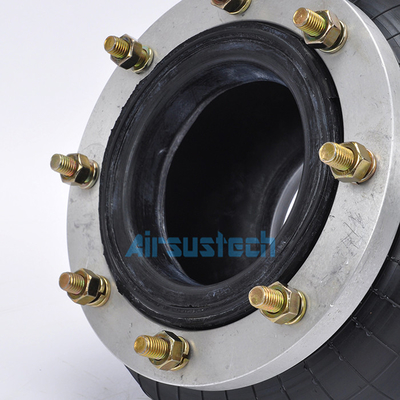

Air Ride Springs 260130H-1 One Covolution Rubber OEM Air Actuator

Specifications and Detailed Technical Parameters: 260130H-1

Nut / Blind Nut

Top Cover Plate Screw (Nut) Tooth : 8×M10

Bottom Cover Plate Screw (Nut) Tooth :8×M10

Gas Hole / Air inlet / Air Fitting

Gas Hole / Air inlet : G1/2

Cover Plate

Top Cover Plate Diameter:210MM

Bottom Cover Plate Diameter: 210MM

Rubber Bellows

Rubber Bellows Natural Diameter : 260 mm

Rubber Bellows Natural Diameter :130 mm

Bumper block / Buffer block

Without Bumper Block

Girdle Hoop / Girdle Ring/Belt Loop

Without girdle hoop/girdle ring/belt loop

Other types

| Model Size | Nominal diameter | The largest diameter(0.7MPA) | Bearing capacity at design height | Natural frequency(0.7MPA) | Stroke | Weight | |||

| 0.2MPA | 0.5MPA | 0.7MPA | Minimum compression height | Height of safe elongation | |||||

| 086060H-1 | 50 | 110 | 44 | 123 | 175 | 5.18 | 42 | 90 | 1 |

| 120060H-1 | 80 | 130 | 122 | 313 | 444 | 3.79 | 42 | 65 | 1.6 |

| 150076H-1 | 104 | 160 | 164 | 435 | 621 | 3.5 | 46 | 85 | 1.4 |

| 188102H-1A | 120 | 210 | 208 | 587 | 862 | 3.05 | 52 | 115 | 2.25 |

| 215120H-1 | 125 | 233 | 294 | 768 | 1109 | 2.83 | 42 | 140 | 2.9 |

| 235118H-1 | 180 | 260 | 474 | 1185 | 1684 | 2.52 | 60 | 136 | 2.6 |

| 235150H-1 | 180 | 260 | 441 | 1205 | 1740 | 2.29 | 65 | 172 | 3.1 |

| 260135H-1 | 170 | 290 | 425 | 1150 | 1670 | 2.4 | 55 | 155 | 2.95 |

| 280126H-1 | 195 | 300 | 643 | 1662 | 2370 | 2.46 | 50 | 144 | 3.75 |

| 320124H-1 | 230 | 340 | 798 | 2071 | 2965 | 2.28 | 52 | 142 | 3.9 |

| 130142H-2 | 80 | 150 | 80 | 219 | 314 | 3.12 | 72 | 162 | 4.4 |

| 156130H-2 | 118 | 170 | 70 | 146 | 3.15 | ||||

| 160166H-2 | 100 | 175 | 149 | 413 | 593 | 2.3 | 82 | 190 | 2.35 |

| 168132H-2 | 120 | 185 | 229 | 589 | 832 | 2.53 | 72 | 151 | 2.2 |

| 200142H-2 | 150 | 220 | 326 | 843 | 1195 | 2.02 | 78 | 162 | 3.05 |

| 220200H-2 | 148 | 250 | 354 | 920 | 1310 | 1.89 | 90 | 229 | 3.22 |

| 230214H-2 | 150 | 255 | 388 | 1023 | 1457 | 1.93 | 88 | 246 | 4.05 |

| 235152H-2 | 180 | 250 | 461 | 1180 | 1667 | 1.91 | 80 | 174 | 3.25 |

| 235210H-2 | 180 | 250 | 80 | 245 | |||||

| 250180H-2 | 185 | 270 | 520 | 1345 | 1904 | 1.74 | 84 | 206 | 3.95 |

| 252163H-2 | 192 | 275 | 422 | 1142 | 1644 | 1.73 | 82 | 238 | 4.2 |

| 260230H-2 | 170 | 290 | 374 | 1036 | 1506 | 1.78 | 90 | 263 | 4.85 |

| 280214H-2 | 200 | 305 | 668 | 1741 | 2480 | 1.68 | 88 | 246 | 5.57 |

| 290265H-2 | 205 | 320 | 440 | 1250 | 1800 | 1.19 | 90 | 303 | 6.55 |

| 300170H-2 | 240 | 320 | 849 | 2156 | 3045 | 1.74 | 85 | 195 | 5.35 |

| 310214H-2 | 230 | 330 | 813 | 2078 | 2992 | 1.89 | 88 | 245 | 7 |

| 330214H-2 | 250 | 355 | 1064 | 2749 | 3897 | 1.65 | 88 | 246 | 7.75 |

| 330254H-2 | 230 | 355 | 861 | 2222 | 3166 | 1.75 | 88 | 290 | 7.24 |

| 350255H-2 | 250 | 380 | 1095 | 2851 | 4098 | 1.45 | 90 | 295 | 8.2 |

| 360214H-2 | 280 | 380 | 1250 | 3220 | 4570 | 1.36 | 88 | 246 | 7.9 |

| 380221H-2 | 300 | 405 | 1432 | 3765 | 5352 | 1.34 | 90 | 255 | 8.5 |

| 400217H-2 | 320 | 430 | 1753 | 4450 | 6300 | 1.66 | 90 | 249 | 11.1 |

| 400255H-2 | 300 | 430 | 1465 | 3752 | 5256 | 1.55 | 90 | 295 | 10.4 |

| 430255H-2 | 330 | 460 | 1760 | 4526 | 6427 | 1.43 | 90 | 295 | 10.2 |

| 480217H-2 | 400 | 510 | 2723 | 6850 | 9700 | 1.27 | 88 | 249 | 13.8 |

| 520217H-2 | 440 | 550 | 3070 | 7850 | 11094 | 1.41 | 90 | 249 | 14.5 |

| 580214H-2 | 500 | 600 | 3978 | 10137 | 14293 | 1.65 | 88 | 246 | 13.3 |

| 630262H-2 | 530 | 660 | 4371 | 10585 | 15801 | 1.48 | 90 | 300 | 19.9 |

| 680262H-2 | 580 | 710 | 5278 | 13596 | 19313 | 1.35 | 90 | 302 | 18.6 |

| 200206H-3 | 150 | 220 | 229 | 634 | 888 | 1.68 | 116 | 236 | 3.75 |

| 250260H-3 | 185 | 270 | 507 | 1344 | 1924 | 1.7 | 116 | 299 | 5.5 |

| 255230H-3 | 200 | 280 | 566 | 1460 | 2070 | 1.3 | 116 | 264 | 5.55 |

| 255322H-3 | 200 | 290 | 116 | 400 | 5.85 | ||||

| 310306H-3 | 230 | 330 | 861 | 2239 | 3170 | 1.3 | 120 | 354 | 7.3 |

| 330306H-3 | 250 | 355 | 1035 | 2730 | 3892 | 1.4 | 120 | 354 | 8.69 |

| 360306H-3 | 280 | 380 | 1250 | 3220 | 4570 | 1.3 | 122 | 360 | 8.25 |

| 380316H-3 | 300 | 405 | 1401 | 3672 | 5235 | 1.32 | 122 | 370 | 10.95 |

| 400312H-3 | 320 | 430 | 1724 | 4436 | 6308 | 1.19 | 122 | 360 | 11.8 |

| 430370H-3 | 330 | 460 | 1716 | 4435 | 6333 | 1.20 | 122 | 430 | 13.8 |

| 480312H-3 | 400 | 510 | 2650 | 6883 | 9768 | 1.17 | 122 | 360 | 16.5 |

| 520312H-3 | 400 | 550 | 3046 | 7932 | 11262 | 1.32 | 122 | 360 | 20.1 |

| 580306H-3 | 500 | 600 | 3950 | 10181 | 14409 | 1.22 | 118 | 354 | 19.16 |

| 630376H-3 | 530 | 660 | 4243 | 11045 | 45612 | 0.94 | 122 | 436 | 24.1 |

| 680376H-3 | 580 | 710 | 5259 | 13620 | 19339 | 1.27 | 122 | 436 | 27.6 |

Three reasons to choose an air spring

1) For the same size air spring, when the internal pressure changes, different bearing capacities can be obtained. This allows the same air spring to adapt to a variety of load requirements, so it is economical. While bearing vertical load, air spring can also bear certain lateral load and transmit torque.

2) Increasing the total volume of the air spring can reduce the natural frequency of the vibration isolation system, which is a unique advantage of the air spring. The volume of the air spring body cannot be too large because the size of the structure space is limited to a certain extent. In order to reduce the natural frequency of the vibration isolation system, an auxiliary air chamber can be set up, and the auxiliary air chamber can be arranged away from the air spring. The volume of the auxiliary air chamber is increased, that is, the total volume of the air spring is increased, and the natural frequency of the air spring vibration isolation system is reduced.

3) The air spring can use the height control valve system to keep the working height of the air spring basically unchanged under different loads. Similarly, through the action of the height control valve, the air spring can have different heights under a certain load, so it can adapt to various structural requirements.

Air springs are used for equipment vibration isolation in industrial machinery

press,

air compressor,

centrifuge,

vibrating conveyor,

control hammer,

foundry machinery and textile machinery,

Optical and Laser Instruments,

integrated circuit,

Ultra-precision machine tools, etc.

The related picture of 260130H-1

![]()

![]()