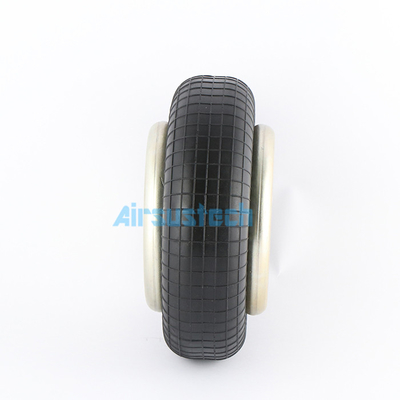

OEM Air Spring Actuator 1B8×4 Replaces Contitech FS120 10 Air Bellow Suspension Single Convoluted

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | 1B8×4 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Warranty: | 12 Months | Material: | Rubber And Mental |

|---|---|---|---|

| Air Hole: | 1/4 NPTF | Condition: | 100% New-brand |

| Shock Absorber Type: | Gas-filled | Convolution Number: | One |

| AIRSUSTECH Part Number: | 1B8×4 | Pressure Ability: | 0.2-0.8 M PA |

| Place Of Origialin: | Guangdong, China | OEM: | YES |

Product Description

OEM Air Spring Actuator 1B8×4 Replaces Contitech FS120 10 Air Bellow Suspension Single Convoluted

Refer Number:

Firestone: W01-358-7564

Firestone: W01 358 7564

Firestone: W013587564

Goodyear: 1B8-550

Goodyear: 1B8 550

Contitech: FS120-10

Contitech: FS120 10

Contitech: FS12010

The detailed Specifications and techical data

| The Max. Diameter | 230mm |

| Air hole/air inlet | 1/4 NPTF |

| Working stroke | maximum 140 mm to minimum 50 mm |

| Top plate screw (nut) teeth | 2×3/8-16UNC |

| Bottom plate screw (nut) teeth | 2×3/8-16UNC |

| Top cover diamete | 135 mm |

| Bottom cover diameter | 135mm |

| Screw center distance | 70mm |

| The air hole distance between the nuts | 35mm |

Min. pressure: 0 bar

Return force to min.height: ≤200N

Overall weight with clamped plates: 2.0kg

Vibration isolation - dynamic characteristic values

Design Height H: recommended 110mm, minimum 90mm

| Pressure p[bar] | 3 | 4 | 5 | 6 | 7 | 8 | Vol. V[l] |

| Force(Load) [KN] | 3.9 | 5.3 | 6.8 | 8.3 | 9.6 | 10.9 | 1.8 |

| Spring rate [N/cm] | 1315 | 1620 | 1925 | 2230 | 2535 | 2840 | |

| Natural frequency [Hz] | 2.9 | 2.8 | 2.7 | 2.6 | 2.6 | 2.6 |

Pneumatic application-static characteristic values

Force F[KN]

| Pressure p [bar] | 3 | 4 | 5 | 6 | 7 | 8 | Vol. V [l] | |

| Height H[mm] | 120 | 3.1 | 4.3 | 5.6 | 6.9 | 8.0 | 9.2 | 1.9 |

| 110 | 3.9 | 5.3 | 6.8 | 8.3 | 9.6 | 10.9 | 1.8 | |

| 100 | 4.5 | 6.1 | 7.9 | 9.7 | 11.0 | 12.4 | 1.7 | |

| 90 | 5.0 | 6.8 | 8.9 | 10.8 | 12.2 | 13.8 | 1.5 | |

| 80 | 5.5 | 7.4 | 9.7 | 11.6 | 13.3 | 15.0 | 1.3 | |

| 70 | 5.9 | 7.9 | 10.3 | 12.3 | 14.2 | 16.0 | 1.1 | |

| 60 | 6.3 | 8.2 | 10.7 | 13.0 | 15.0 | 17.0 | 0.9 | |

Factors affecting air springs

- Own material. The synthetic material for the air spring needs to have excellent thermal conductivity because the pressure changes inside the air spring produce extremely high temperatures. Guomat uses the highest quality heat-resistant natural rubber. At the same time, rubber also needs to have good oil resistance, oil resistance, dirt resistance and ozone resistance, even if the sun is shining, will also affect the durability of rubber.

- Geometry. The seal film needs to be able to maintain measured air volumes at different pressures. The film wall thickness can be adjusted to maximize comfort and durability. In general, thinner wall thickness results in faster, smoother response times and better ride comfort, but it also affects film durability to some extent. The strength of the rubber film can be increased by adding a fiber layer, in which the linear structure can be braided along the axial (meridional) direction, or by using a cross structure. Axial braided construction reduces wall thickness, but additional restraints are often required to prevent the balloon from overexpanding and bursting.

Rotary surface type air spring assembly

1. Concealed nut; 2 Air inlet (air enters the tapered hole of the air bag); 3. Rim plate (permanently crimped on the air bag at the factory, strict component leakage before shipment test); 4. Rubber bladder; 5. Girdle Hoop/Belt Loop(With/ Without)

The reated picture

![]()

![]()

![]()