Goodyear 2B12-425/311 Double Convoluted Air Spring AIRSUSTECH Air Spring Assembly

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | 2B 6330 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Warranty: | 1 Year | Material: | Rubber And Mental |

|---|---|---|---|

| Packing: | Strong Carton | Condition: | 100% New-brand |

| Shock Absorber Type: | Gas Filled | Sample: | Acceptable |

| Cross Reference: | Goodyear 2B12-425/311 | OEM: | Welcome |

| Application: | Industrial Air Spring | Convolutions: | 2 |

Product Description

Goodyear 2B12-425/311 Double Convoluted Air Spring AIRSUSTECH Air Spring Assembly

Cross Reference

|

Good Year: 2B12-425 Good Year: 2B12-311 |

Navistar: 1685179C1 Hendrickson: 1VA1816 Ridewell: 1003587180C |

|

Contitech: FD 330-22 363 Contitech: FD 330 22 363 Contitech: FD 33022363 |

SAF Holland: 57007180 |

|

Firestone:W01-358-7180 Firestone: W01 358 7180 Firestone: W013587180 Firestone: WO13587180 Firestone: WO1 358 7180 Firestone: WO1-358-7180 |

Watson&Chalinl: AS01541 G/01881F |

|

Triangle: 6316 Triangle: 4363 |

Peerless: 0550 00001 |

|

Airkraft: 11506 1/3B-356 Vibracoustic: VSP2B22R7180 EI Rise: 8030190 Kwiklok/Todco(Jifflox) Leland: Sc2075 |

The detailed Specifications and parameters

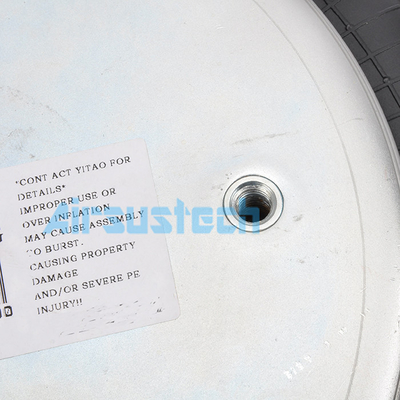

Blind Nut/Screw teeth

Screw teeth of the top plate: 2×3/8UNC

Screw teeth of the bottom plate: 2×3/8UNC

The screw center distance: 157mm

Air inlet/Air hole/Air fittings

1/4NPTF

The distance between the screw center and the air inlet:73mm

Cover plate

Top cover plate:231mm

Bottom cover plate:231mm

Rubber Max. OD: 325mm

Height

Min. height: 81mm

Max. height: 305mm

Bumper block: Without

Girdle ring/Girdle hoop/belt loop: one piece

The reated picture

![]()

![]()

Application

Rubber air springs are widely used in industrial machinery for shock absorption of equipment. It plays a role in buffering shock absorption, controlling movement or supercharging in various mechanical devices. Compared with air cylinders or other elastic elements with the same function, rubber air springs have simple structure and reliable operation, do not require complex parameter calculation and structural design, have no seal leakage problems, are easy to use and maintain, and have a long service life.

1. Lifting equipment

Traditional lifting equipment uses air cylinders or hydraulic cylinders to lift objects, which requires a large installation space, is difficult to manufacture, heavy in weight, prone to leakage and inconvenient to maintain. After using the rubber air spring as the lifting element of the lifting equipment, the traditional shortcomings of the lifting equipment are overcome, maintenance is not required, the service life is long, and the operation and replacement are convenient. Therefore, rubber air springs are gradually replacing cylinder products on lifting equipment.

2. Vibration damping equipment

The advantages of high frequency vibration isolation, sound insulation and low natural vibration frequency of the rubber air spring can better realize vibration isolation and ensure the safety and stability of the base of the vibration equipment and the control system. Therefore, rubber air springs are widely used in equipment such as vibration isolation of vibrating screens and vibration reduction of luxury vehicle seats.