Front Or Rear Suspension Air Springs NORGREN M/31121 PARKER 9109044

Product Details:

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | 1B12×1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Place Of Origin: | Guangdong, China | Material: | Rubber + Steel |

|---|---|---|---|

| Certificate: | ISO/TS16949:2009 | Warranty: | One Year |

| Packing: | Neutral Box Or As Customers' Request | Type: | Air Spring |

| Position: | Front Or Rear | HS Code: | 8708809000 |

| Pressure Ability: | 0.2-0.8 M PA | Cross Reference: | NORGREN M/31121 PARKER 9109044 |

| High Light: | 9109044 Suspension Air Springs,M/31121 Suspension Air Springs |

||

Product Description

NORGREN M/31121 PARKER 9109044 Single Convoluted Industrial Suspension Air Springs

Cross Reference

Air spring supplier/competitor: NORGREN

supplier/competitor number: M/31121; M 31121; M 31121

Air spring supplier/competitor: PARKER

supplier/competitor number: 9109044

Air spring supplier/competitor: FIRESTONE

supplier/competitor number: W01-R58-4060; W01 R58 4060; W01R584060; WO1-R58-4060; WO1 R58 4060; WO1R584060

Air spring supplier/competitor: DUNLOP

supplier/competitor number: SP 1640;SP1640

Air spring supplier/competitor: DUNLOP PNEURIDE

supplier/competitor number: 12" x 1

Air spring supplier/competitor: CONTITECH

supplier/competitor number: FS 412-10 DS; FS412-10DSG1/2; FS 412 10 DS G1/2; 67962

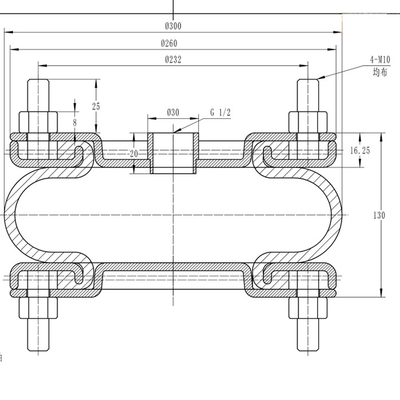

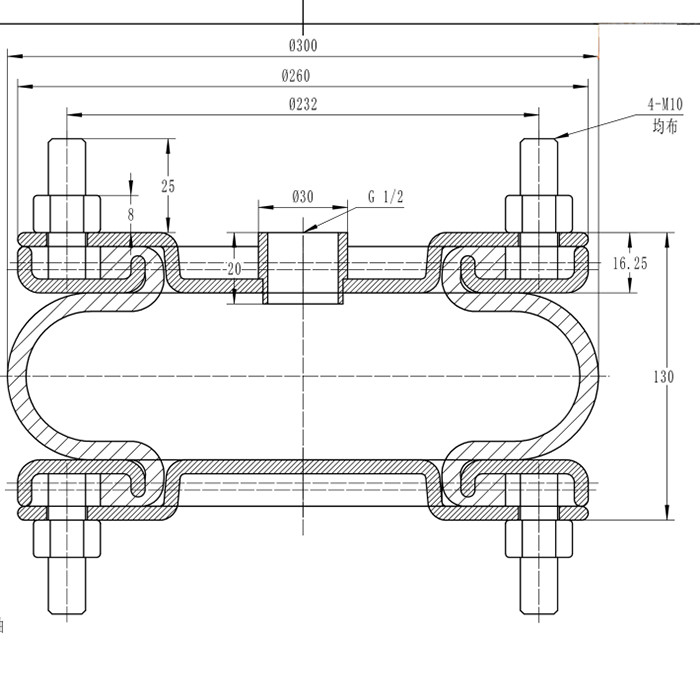

Specifications and Detailed Technical Parameters:AIRSUSTECH 1B12X1

Top plate bolts/studs: 4pcs×M10

The screw center on top plate: 232mm

Bottom plate bolts/studs: 4pcs×M10

The screw center on bottom plate: 232mm

Top plate diameter: 260mm

Bottom plate diameter: 260mm

Air inlet/air fittings: G1/2

Rubber Bellow diameter: 300mm

Height: 130mm

Girdle hoop: Without/No

Working pressure≤0.7Mpa

Working medium: water, air, a small amount of oil

Fatigue test: ≥ 1 million times

Burst pressure: ≥2.0Mpa

Operation

Due to their flexible construction the mounting of Air Bellows is less critical than with conventional pneumatic cylinders, which normally require rigid fixing and guidance and provide only one axis within a limit of 15° between faces. Additionally the axial location of the end plates may be off set by up to 10 mm.

When pressurised Air Bellows will follow the line of leased resistance. Accordingly care must be taken with the mounting geometry in angled applications.

When depressurised Air Bellows will fit in to surprisingly small spaces, especially useful for clamping or moving awkwardly shaped or very heavy loads. In operation it is recommended that the unit is not allowed to "bottom out" or achieve its maximum height. Various mechanical devices may be employed to achieve this.

Applications

|

Roller tensioning Hot foil stamping press Short stroke mechanical linkage Hopper vibration and damping Platform lift Machine isolation Scissor lift Mechanical handling stop |

Features

Air spring, commonly known as air bag, air bag cylinder, leather bag cylinder, air shocks, air spring assembly, air spring completer, rubber bellow, air suspension, air suspension bag, air supension spring, air balloon, air actuator, air pillow

Overload safe, Easy to limit force, Easy to vary speed, Reliabifity, Low installaton cost, Ease of servioe, Safety in dammp envirommments, Safety in explosive atmospheres, Safety risk with electrical, installations, Clean hygienic,Competitive purchase price, Long service life, Light weight, Lower noise level during operation

The related picture of 12×1

![]()

![]()