Black Industrial Air Springs S200 2R S200-2 Yokohama Double Convoluted Punch With Cover

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | F-200-2 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Material: | Rubber And Steel | Certificate: | ISO/TS16949:2009 |

|---|---|---|---|

| Warranty: | 12 MONTHS | Number Of Convolutions: | Double |

| Packing: | Neutral Box Or As Customers' Request | Type: | Air Springs |

| Cross Reference: | Yokohama S 200 2R | HS Code: | 8708809000 |

| Color: | Black | Quality: | 100% Tested |

| High Light: | S200-2 Yokohama Industrial Air Springs,Industrial Air Springs With Cover |

||

Product Description

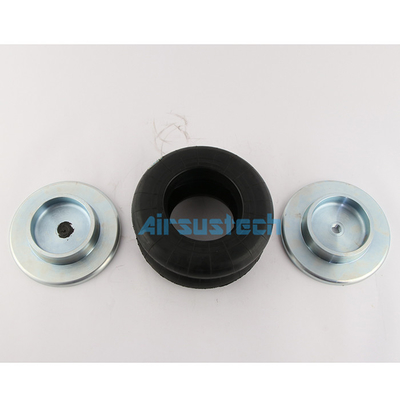

S200 2R S200-2 Yokohama Double Convoluted Punch Industrial Machines Air Springs With Cover

Cross Reference

|

AIRSUSTECH Part No.: F-200-2 |

|

Reference |

|

YOKOHAMA S-200-2R |

Specifications and Detailed Technical Parameters: F-200-2

Height(mm)

Design Height: 98

Max. Height:148

Min Height: 53

Standard height, approximate value at 0.49MPA internal pressure

Effective Area(cm2) : 315

Volume(L) : 3.2

Load(KN): 15.4

Dynamic Spring Constant(n/mm): 373

Natural Vibration Frequency(Hz): 2.5

Maxi inner Pressure Limited(Mpa): 0.88

Burst Inner Pressure(Mpa): 2.9-3.9

Max stroke (mm): ±35

Compression Max. Outside Diameter: 260mm

Girdle hoop: 1 piece

Top plate mounting threads qty: 4pcs

Bottom plate mounting threads qty: 4pcs

Applications: Punch machines or Others

Punch air spring/air bag

Self-sealing is named for its self-sealing without external force. As shown in the figure, when the rubber flexure is reinforced with a fiber layer, the steel (galvanized) waist ring that prevents expansion will be placed in it.

The steel traveler at the end of the cover plate uses the internal pressure of the air to deform the rubber mouth and make close contact with the upper and lower cover plates (galvanized), thereby preventing air leakage.

The upper and lower cover plates are formed by machining.

The air hole is a pipe threaded air intake hole for the installation of the air intake line

Threaded holes for mounting

How to install the upper and lower plates

Gently fit the upper and lower plates with the air spring, and then gradually send in compressed air after height restriction to increase the internal pressure, and the upper and lower plates can be automatically fitted with the air spring to achieve sufficient airtightness. If internal pressure is applied without height restriction, the upper and lower plates will collapse. Therefore, the upper and lower plates must be placed on a device with considerable strength that can limit the height for pressurization. If there are foreign matter, rust, oil stains, etc. on the sealing parts of the air spring and the upper and lower plates, they should be cleaned before operation. In addition, apply some soapy water to the connecting part of the rubber and the upper and lower plates, it will be easier to fit.

How to disassemble the upper and lower panels

Insert a crowbar with a flat front end into the connection between the air bomb and the upper and lower plates, and pry it hard to disassemble it. To avoid prying forcefully in one place, it should be disassembled in several places in order to prevent damage to the air spring.

The related picture of F-200-2

![]()