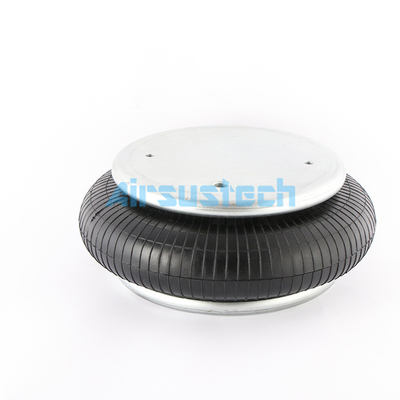

Weforma WBE 500-E4 1/4 NPT Industrial Air Springs Replacement Rubber Bellows For Packaging Machines

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Certification: | ISO/TS16949:2009 | Material: | Rubber And Steel |

|---|---|---|---|

| Quality Assurance: | 12 Months | Convolution: | Single Convoluted |

| Packing: | Neutral Box Or As Customers' Request | Type: | Industrial Air Springs |

| Cross Reference: | Weforma WBE 500-E4 | Air Inlet: | 1/4NPT |

| High Light: | Weforma WBE 500-E4 Industrial Air Springs,Rubber Bellows Industrial Air Springs |

||

Product Description

Weforma WBE 500-E4 1/4 NPT Industrial Air Springs Replacement Rubber Bellows For Packaging Machines

Cross Reference

Weforma WBE 500-E4

Weforma WBE 500 E4

Weforma WBE500-E4

Weforma WBE500 E4

Weforma WBE500E4

Specifications and Detailed Technical Parameters

HS Code: 8708809000

Air inlet: 1/4NPT, Offset

Girdle hoop: Without

Type: Industrial air springs

Single Convolution

Condition: 100% New

Other model we could offer and details

|

Weforma model number reference |

Details |

|

WBE 500-E1 / WBE 500 E1 / WBE500-E1/ WBE500 E1 / WBE500E1 |

G1 |

|

WBE 500-E2 / WBE 500 E2 / WBE500-E2/ WBE500 E2 / WBE500E2 |

G1/4 |

|

WBE 500-E3 / WBE 500 E3 / WBE500-E3/ WBE500 E3 / WBE500E3 |

G3/4 |

|

WBE 500-E5 / WBE 500 E5 / WBE500-E5/ WBE500 E5 / WBE500E5 |

3/4 NPT |

Air springs can be used in packaging machines

Air springs or air bags are used in packaging machines as actuators to provide controlled and consistent motion during the packaging process. They can be used to precisely maintain the position of a packaging material or to ensure that a packaging component is correctly aligned during sealing or cutting. Air springs can also be used to provide vibration isolation, which helps to reduce wear and tear on packaging machines and can result in higher quality packaging. Some examples of packaging machines that use air springs include form-fill-seal systems, bag loading machines, and machinery for vacuum packaging.

To properly store air springs, you should follow these general guidelines

1. Clean the air springs: Before storing air springs, make sure that they are clean and free of any dirt or debris. You can use a soft cloth or a brush to clean them.

2. Deflate the air springs: Release all of the air pressure from the air springs before storing them. This prevents them from developing flat spots or other deformities that can lead to performance issues down the line.

3. Store the air springs in a dry location: Moisture can cause damage to air springs, so it's important to store them in a dry location. Avoid storing them in areas prone to flooding or excessive humidity.

4. Protect the air springs from damage: When storing air springs, make sure they are protected from damage. You can wrap them in a soft cloth or place them in a container to prevent them from being scratched or dented.

5. Check the air springs periodically: If you're storing air springs for an extended period of time, it's a good idea to check on them periodically to make sure they haven't developed any issues. If you notice any damage or signs of wear and tear, it may be time to replace them.

The photos

![]()

![]()