W01-358-0119 Industrial Air Springs Style 119 Firestone Single Convoluted Bellows

Product Details:

| Brand Name: | AIRSUSTECH |

| Model Number: | 1B0119 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Place Of Origin: | Guangzhou, China | Certification: | ISO/TS16949:2009 |

|---|---|---|---|

| Material: | Rubber | Warranty Period: | One Year |

| Packing: | Neutral Box Or As Customers' Request | Type: | Industial Air Springs |

| HS Code: | 8708809000 | Cross Reference: | Firestone W01-358-0119 |

| High Light: | W01-358-0119 Industrial Air Springs,Single Convoluted Bellows Industrial Air Springs |

||

Product Description

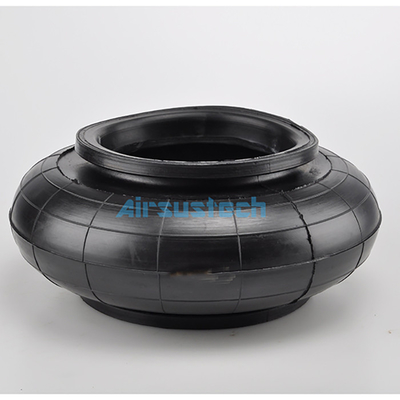

W01-358-0119 Style 119 Firestone Single Convoluted Bellows Industrial Air Springs

Cross Reference

|

Firestone W01-358-0119 / W01 358 0119 / W013580119 Firestone WO1-358-0119/ WO1 358 0119 / WO13580119 Firestone style 119 |

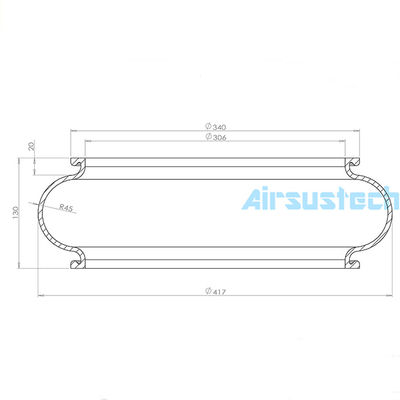

Specifications and Tecnical Data

Rubber bellow diameter: 417mm

Height: 130mm

Opnening diameter: 306mm

Single Convolution

Industrial air springs

Rubber material

HS Code 8708809000

Sample is available

100% Condition New

Without girdle ring

Without rubber bumper

Two Ply Bellows

Air spring bellow

We also could offer Firestone assembly number W01-M58-6974

Firestone style 119

Two Ply Bellows

Ribbed neck aluminumbead rings (equal spacing) ,45 mm bolts, nuts, washers

Firestone assembly order number: W01-M58-6974 / W01 M58 6974 /W01M586974 / WO1-M58-6974 / WO1 M58 6974 /WO1M586974

Ribbed neck aluminumbead rings (equal spacing).1 7/8 bolts, nuts, washers

Firestone assembly order number: W01-358-7478 / W01 358 7478 / W013587478 / WO1-358-7478 / WO1 358 7478 / WO13587478

Rolled plate assembly, 1/2 blind nuts, 3/4 NPT

Firestone assembly number W01-358-7477 / W01 358 7477 / W013587477 / WO1-358-7477 / WO1 358 7477 / WO13587477

Air spring applications

The principle of working of an air spring is to use compressed air as a power source to support the weight of the vehicle. When a load is applied to the air spring, the air inside compresses, which in turn increases the spring rate. When the load is removed, the air expands, and the air spring returns to its original position. This allows the air spring to provide a smooth ride and absorb shocks and vibrations. The basic working principle of air spring is to transfer load by compressing and expanding the air inside the spring.

Air spring applications refer to various uses of air springs in various industries. Air springs are used to provide suspension and vibration isolation in heavy machinery, automotive, and rail applications. They are also used in vibration isolation systems for buildings, bridges, and other large structures. Air springs are commonly used in truck and bus suspensions, where they provide a comfortable ride and improved handling. They are also used in agricultural machinery, construction equipment, and other heavy-duty applications. In addition, air springs can be used to support and lift loads in industrial applications, such as assembly lines and material handling equipment. The use of air springs is becoming increasingly popular in various industries due to their numerous benefits, including durability, reliability, and versatility.

One key aspect of air spring maintenance is ensuring that they are properly inflated to the manufacturer's recommended pressure levels. This can help to prevent damage and improve overall performance. It's also important to inspect the air springs regularly for signs of wear or damage and to address any issues promptly to avoid further damage or potential safety hazards.

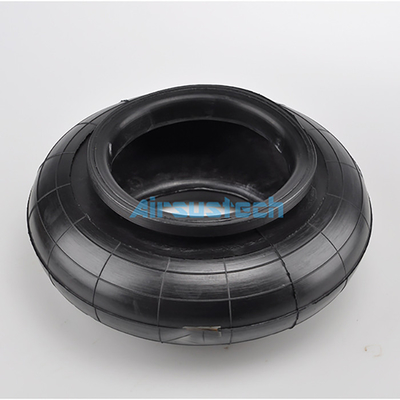

The image of industrial air springs

![]()