Single Convoluted SP2008 Dunlop Air Spring 4.5×1 AIRSUSTECH Air Bellow Bag

Product Details:

| Place of Origin: | Guangzhou China |

| Brand Name: | AIRSUSTECH |

| Certification: | ISO/TS16949:2009 |

| Model Number: | 1B4.5×1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3Pieces |

|---|---|

| Packaging Details: | Strong Carton Box or as Customers Requirement |

| Delivery Time: | 5-8 Working Days |

| Payment Terms: | T/T, Western Union, Paypal or Others |

| Supply Ability: | 1000PCS/Week |

|

Detail Information |

|||

| Material: | Rubber + Steel | Certificate: | ISO/TS16949:2009 |

|---|---|---|---|

| Warranty: | One Year | Number Of Convolutions: | 1 |

| Packing: | Neutral Box Or As Customers' Request | Size: | 24×24×24 Cm |

| Type: | Air Spring | Position: | Front Or Rear |

| Oe No.: | Dunlop SP2008 | Pressure Ability: | 0.2-0.8 M PA |

| High Light: | SP2008 Dunlop Air Spring,Single Convoluted Dunlop Air Spring,TS16949 Dunlop Air Spring |

||

Product Description

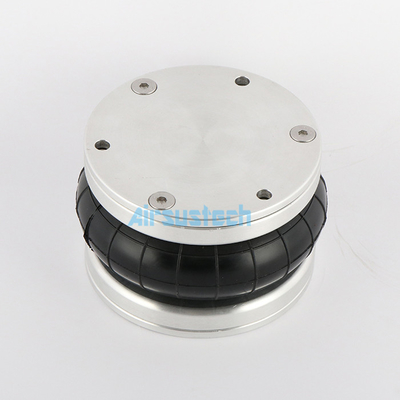

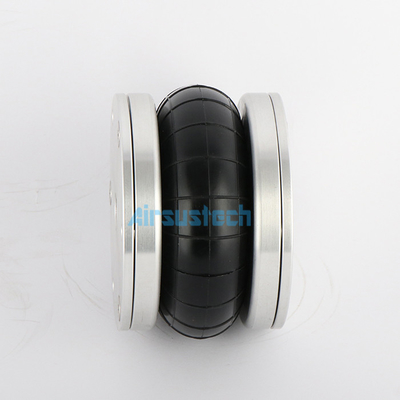

Single Convoluted SP2008 Dunlop Air Spring 4.5×1 AIRSUSTECH Air Bellow Bag

OEM NO.

| Airsustech | 4.5×1 |

| DUNLOP | 4 1/2 X 1 | |

| Dunlop | SP2008 |

| Dunlop | SP 2008 |

| Dunlop | 4.5x1.Aluminuim |

| FIRESTONE | W01R584043 |

| FIRESTONE | W01-R58-4043 |

| FIRESTONE | W01 R58 4043 |

Specifications and Detailed Technical Parameters:AIRSUSTECH 1B4.5×1

Operation mode: single action

Stroke length: 40 mm

Stomatal size: G3/8

Nominal diameter: 4-1/2"

Operation mode: single action

Working pressure: 0 ... 8 bar

Working temperature: -30 ... 50°C

Stroke length: 80 mm

Theoretical power: 5750 N

Certification-REACH: available on request

Certification-RoHS compliant: available on request

Size-Diameter: 125.0 mm

Size-Length: 65.0 mm

Size-weight: 0.950 kg

Size-Unit of Measurement: EA

The related picture of 4.5×1

![]()

![]()

Production air spring steps

1. Rubber mixing: sports and rubber processing

2. Making rubber bellows: usually one layer of rubber inside, two layers of cord in the middle, and one layer of rubber on the outside. Then connect them together by fixing the mold.

3. Use molds to make other molding accessories, such as plastic parts, iron seats, aluminum seats, iron plates and other hardware accessories

4. Bellows and other accessories are mechanically assembled to make air springs.

5. Air tightness test: Fill the produced air spring with air every time, and then put it into water to test whether it is bubbling and leaking.

6. Quality monitoring: blasting test, fatigue test. The blasting pressure of the air spring in the GUOMAT factory is as high as 30 atmospheres, and the fatigue resistance reaches 3 million times, reaching international standards.

7. Packaging and transportation: Qualified products are usually packaged in carton boxes. Some special solid wooden boxes are required, and others are labelled and packaged according to customer requirements.